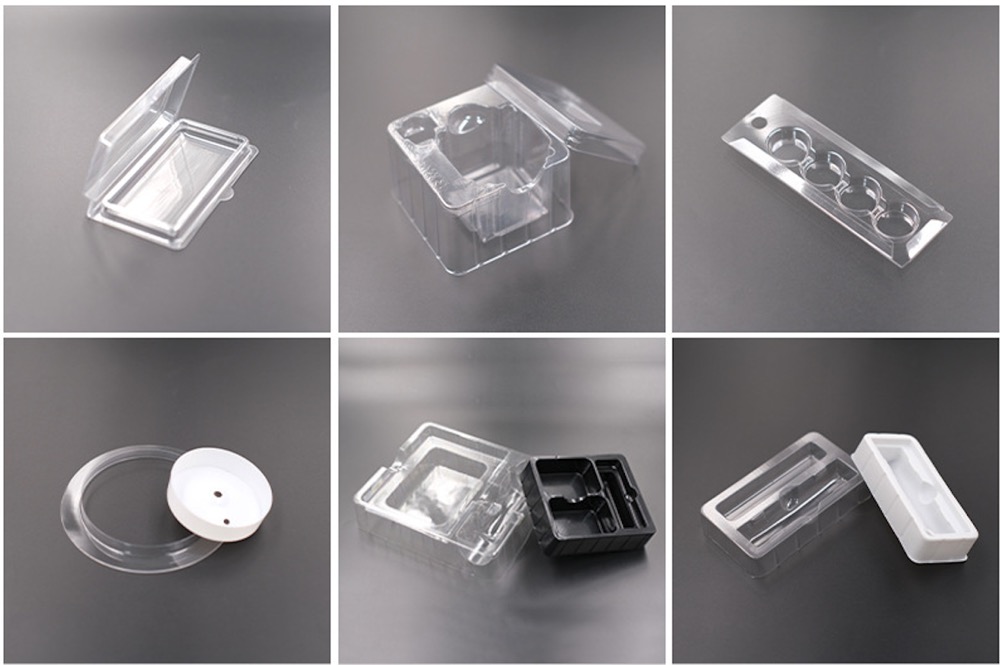

Different Blister Plastic Packing Film

The blister process is a plastic thermoforming technology that heats the plastic packing film to a certain temperature, then attaches to the surface of the mold and use vacuum adsorption to thermoform. Vacuum blister process is widely used in packaging, stationery, toys, advertise and other applications.

Plastic packing films are divided into two categories, thermoplastics and thermosetting plastics, which according to their heating behavior. Most of the materials used for blister thermoforming process are thermoplastic plastic film, like PVC, PET, TPU, etc.

PVC blister packing film is without white when fold, little shrinkage rate and crystalline impurities, which has good flatness, clear color, waterproof and moisture-proof, good flame retardancy, strong stamping resistance, good wear resistance, and plastic flat effect, vacuum plastic without wrinkle.

PET blister film is colorless, odorless, tasteless, non-toxic, which has excellent transparency, excellent mechanical strength, wear resistance and electrical insulation properties, good creep resistance, rigidity and strength. Blister-formed PET boxes, etc., can be in direct used for food packaging because of its excellent hygiene.

TPU blister film is increasingly widely used in shoe sole blister films, equipment protective films, dental invisible aligner, etc. due to its excellent toughness, heat resistance, elasticity, cold resistance, as well as its non-toxic and environmentally friendly advantages.

POLYSAN is a good China blister film manufacturer, we supply top quality PVC blister packing film, PET blister packing film, TPU blister packing film.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe