The Production Process Step of TPU Hot Melt Adhesive Film

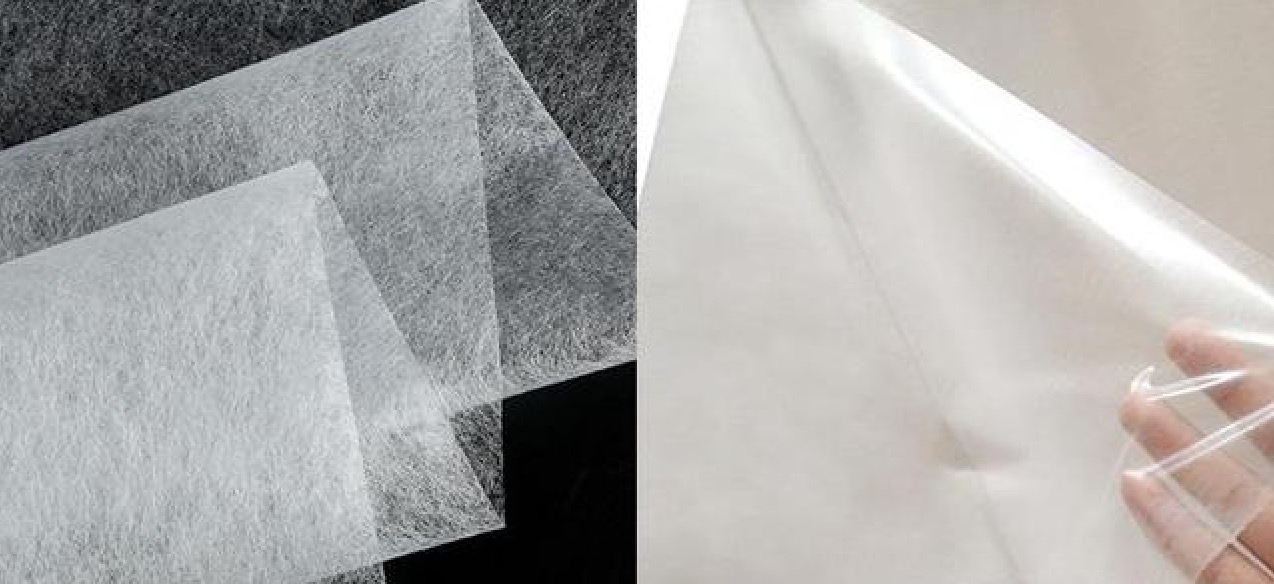

TPU hot melt adhesive film is a type of high-performance adhesive film with high temperature resistance, low temperature resistance, water resistance, dry cleaning resistance and good impact resistance.

The production process of TPU hot melt adhesive film flowing as below.

1. Raw material preparation

Mix TPU resin, adhesive and other additives in a certain proportion to make TPU hot melt adhesive particles.

2. Melt extrusion

Heat and melt the TPU hot melt adhesive particles in the extruder. Thee molten material will be extruded as continuous hot melt adhesive film.

3. Cooling and solidification

Place the extruded hot melt adhesive film on the cooling roller, which will be fast cool and solidify through heat transfer and natural cooling.

4. Cutting and embossing

The cooled and solidified hot melt adhesive film is analyzed and processed through cutting, embossing and other processing and production techniques to make hot melt adhesive film products of various structural sizes and shapes.

5. Packaging and storage

TPU hot melt adhesive film is packaged according to specifications and stored in dry, ventilated and dark conditions to ensure product quality and performance.

It is important to control the production temperature, flow rate and pressure, to ensure the TPU hot melt adhesive film be in stable good quality.

POLYSAN company produce and supply excellent quality hot melt adhesive glue film, customized for thickness, melting temperature and color, widely applicate in textile, clothing, shoes and hats industry, luggage industry, automotive interior parts industry, furniture industry.

English

English  Русский

Русский  Deutsch

Deutsch  Français

Français  Português

Português  Español

Español  Italiano

Italiano  العربية

العربية  한국어

한국어  Türkçe

Türkçe